As the world moves inexorably towards mass use of sustainable energy, the race is on to ensure its sources are truly sustainable – in other words, consistent and efficient. Maintenance costs remain high in certain sectors due to various factors, not least of which is the weather. Dependent on where the installation is determines how much of a factor conditions are; in the case of solar power it’s often a constant battle to keep modules clean and free from dust, sand etc. If left alone, dirty modules can hugely reduce their power efficiency.

One area that is being increasingly examined is that of self-cleaning coatings, substances that do exactly what they say on the tin, thus reducing maintenance and costs while maintaining performance over time.

However, while the theory may be sound the reality is (as yet) somewhat different. Here we take a look at some of the areas that need to be considered when looking into the world of self-cleaning coatings.

1. Self-cleaning or easy clean coatings don’t need to be hydrophobic or super-hydrophobic

Hydrophobic & super-hydrophobic coatings are effective against moisture (due to their lotus leaf effect which repels water by causing it to bounce off). So why would they be needed in arid and dusty regions? Well aside from the humidity factor – which is often an issue in these regions and can create a ‘cake & bake effect’ in soling terms – having hydrophobicity attributes integrated into a coating formulation are and will be a critical component to achieve a coating which is abhesive and repels all forms of soiling contamination.

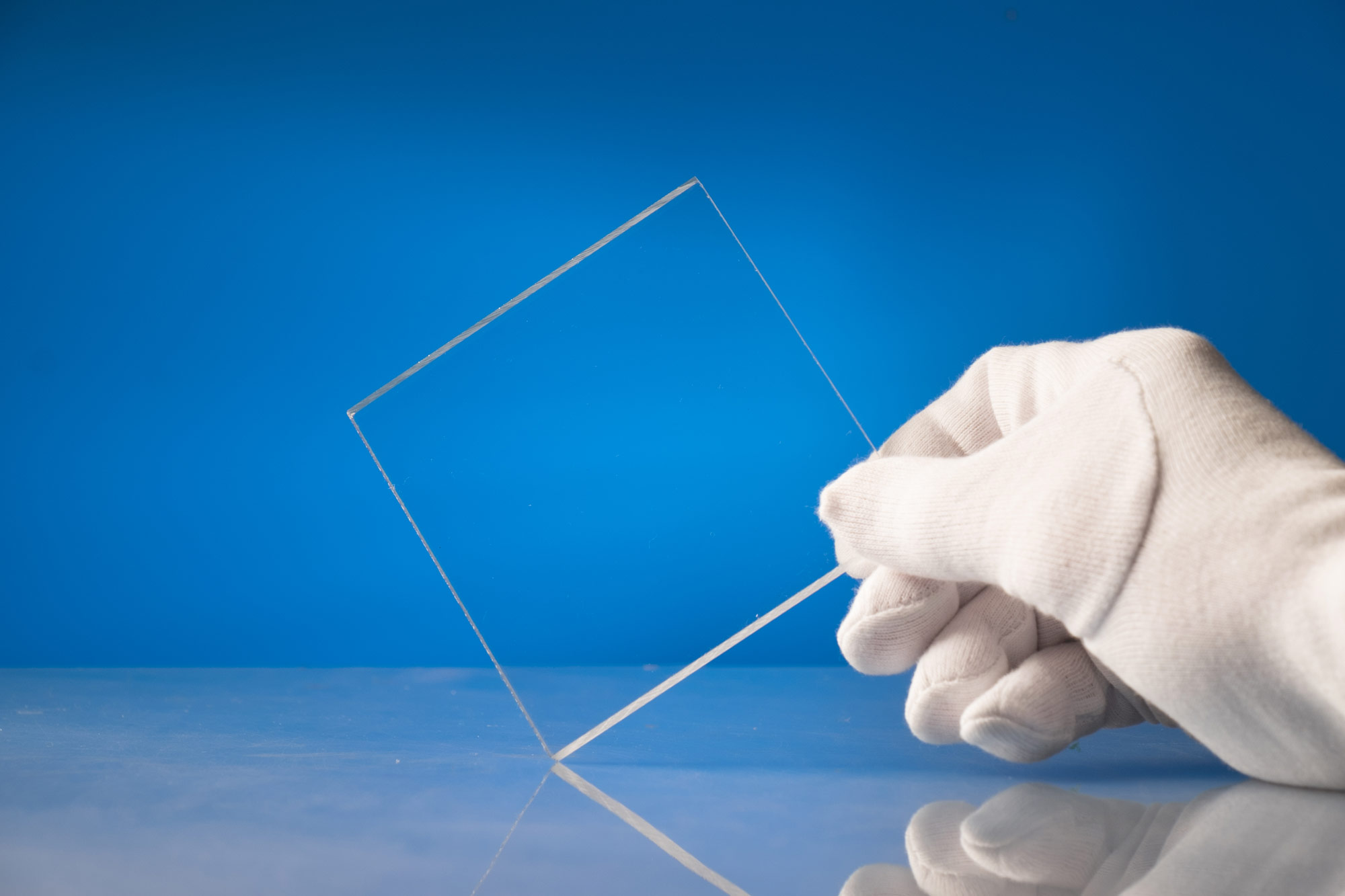

2. Anti-reflective coatings can be adapted to self-clean or easy clean

Current anti-reflective coatings are durable and integrated into the PV manufacturing process of PV modules. They need to be durable to last the lifetime of the module. Recently some AR coating manufactures have adapted AR coatings, leveraging core AR properties and durability to produce self-cleaning/easy clean coatings. But even they recognise that the coatings’ successful operation has been influenced by local environmental factors (such as the different types of soiling) and will need to be ‘tuned’ for each environment.

3. Coating reapplication is not required with self-cleaning materials

This is of course the eventual goal of any self-cleaning material. The reality is that maintenance is still required, as the coatings currently available don’t deliver high durability over time. As a result O&M costs remain high, with endless water usage (an increasingly scarce global resource) among the key challenges for the industry. However, self-cleaning or easy clean coatings allow for water use reduction, which is an important step forward. As a result O&M costs remain high, with endless water usage.

4. One size fits all – technology advances mean there is no demand for bespoke coatings

Harsh climates with extreme weather conditions can be detrimental to a coating’s overall performance and solar modules installed in arid deserts, for example, are subject to wholly different environmental conditions compared to those installed in temperate climates. The ability to fine-tune a coating’s chemical properties according to its geographical location is key from a performance, operational, and economical perspective and makes deployment more effective in the long run.

5. ‘Smart’ coatings won’t / can’t deliver on all of the above

The effectiveness of a “Smart” coating depends on how clever you are during manufacture. By recognising unique challenges of different climate types and deploying a “material by design” approach to industrial coatings manufacturing processes, it’s possible to develop coatings that can withstand all environmental conditions, regardless of location, resulting in optimal ROI. Additionally this disruptive approach does not rely on the adoption of an anti-reflective coating but is focused on a self-cleaning coating designed to do the job and incorporate all the critical attributes: anti-reflective, self-cleaning , durable, hydrophobic, transparent and UV resistant.

How can we help?

We are a forward thinking & progressive company that’s on a mission to facilitate the widespread adoption of a materials by design approach to industrial coating manufacture.

With capabilities ranging from bespoke design, synthesis and supply chain establishment we can provide a complete service in the development and establishment of next-generation coating materials for all solar PV applications.

Visit www.SolarSharc.com to follow the development of our newest ground-breaking solar PV coatings