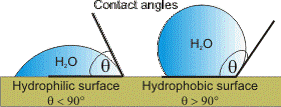

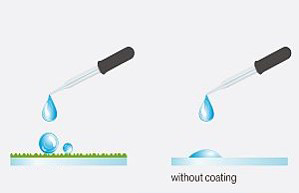

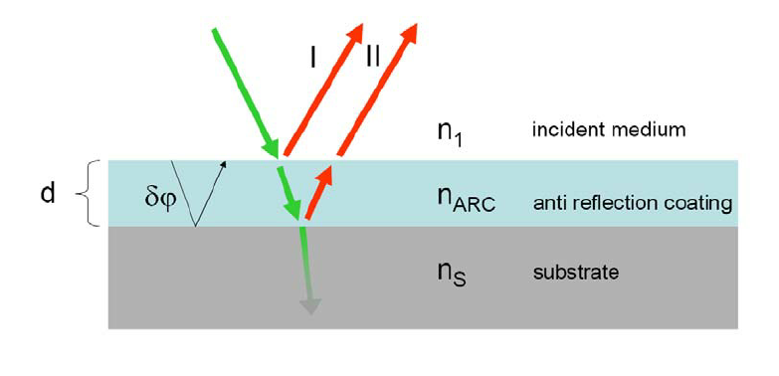

Solar Sharc® has demonstrated a combination of high water repellency (105° contact angle by sessile drop test) – an 80° improvement compared to unmodified resin, excellent resistance to abrasion 200 cycles Taber linear abrasion test CS8 abrasive compared to 50 cycles with no additive), long life (1000 hours damp heat test 85°C/85%RH with no loss of repellency – equivalent to 25 year life) and very high transparency Below is a technical overview of the optical and repellent performance of Solar Sharc® generation 1 (D15.G1.) This is early incarnation of the Solar Sharc® coating and demonstrates both the testing methodology and initial results.

Development Specification

Glass

Solar Sharc® G1 (D15G1) coated glass

DOI

96.5

97.1

Refractive Index (n)

1.5 - 1.6

1.35

Transmittance

91-92%

94.40%

Water Contact Angle

40º

107.1 º

Diiodo Contact Angle

50º

72.7 º

Thickness

-

2μm (microns)

UV exposure resistance (50 hours) − WCA after UV exposure − Transmittance after UV exposure

-

106⁰ (-1%) low degradation. 93.4% (-1%) low degradation.

High temperature (85ºC) and High Humidity (85%) exposure resistance (500 hours): − WCA after HT and HH exposure − Transmittance after HT and HH exposure

-

95⁰(-11%) Low degradation. 93% (-1%) (Low degradation).

Thermal cycling resistance (-40ºC to 85ºC) (100 cycles) − WCA after thermal cycling − Transmittance after thermal cycling

-

105⁰ (-1%) Low degradation. 93% (-1%) (low degradation).

Sand impact test - WCA after sand impact test

-

87⁰(-19%) Partial degradation.

Visualising Hydrophobicity

Visualising Anti Reflectiveness

Downloads: Sharc Lite